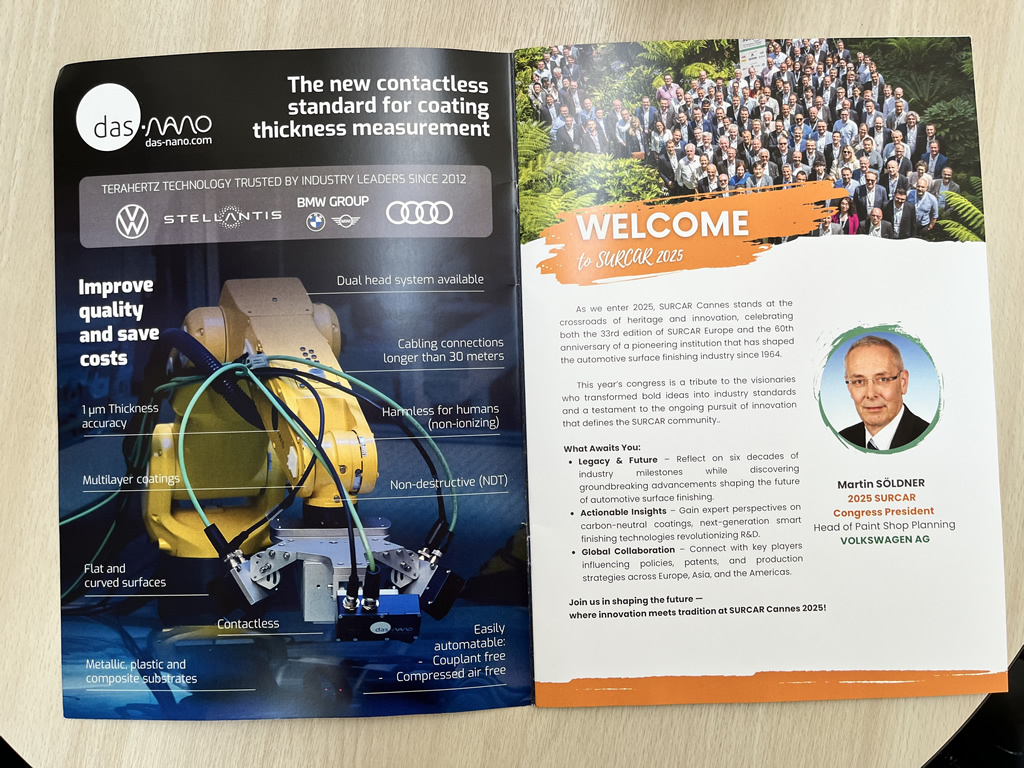

- Trusted by industry leaders since 2012

The power of terahertz: lowering costs, enhancing quality

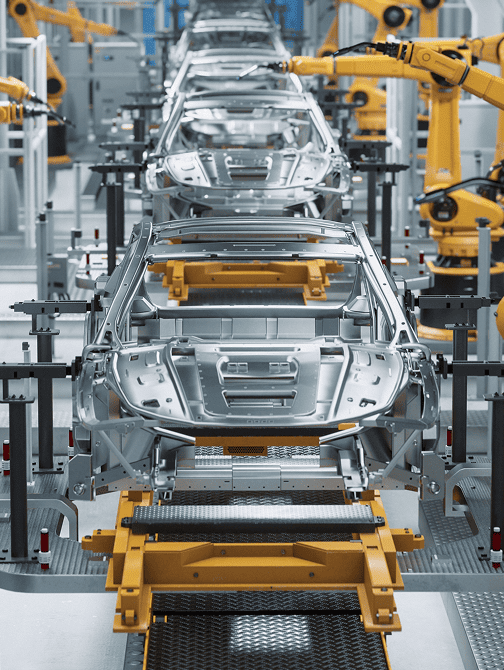

Proven innovation, driving industries worldwide

- Built for the long term

Our technology isn’t just built to challenge the status quo—it’s built to last. Das-Nano powers 85% of all industrial terahertz installations worldwide, delivering 24/7 reliability and precision across industries.

We don’t just improve quality—we guarantee 100% cost reduction and quality enhancement for leading manufacturers.

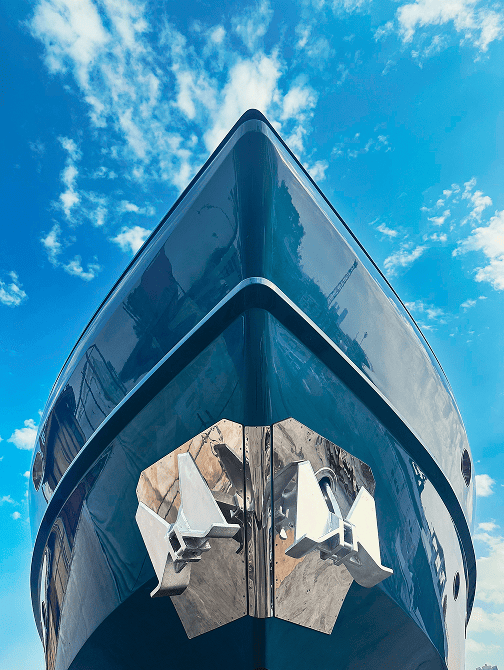

- Industries

Redefining measurement standards across industries

- Products

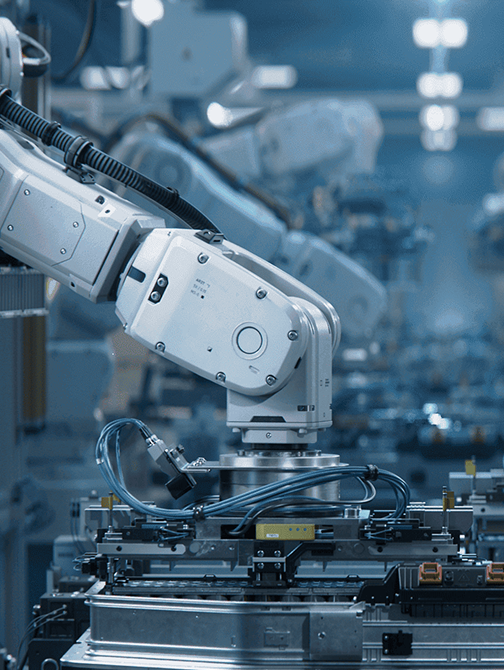

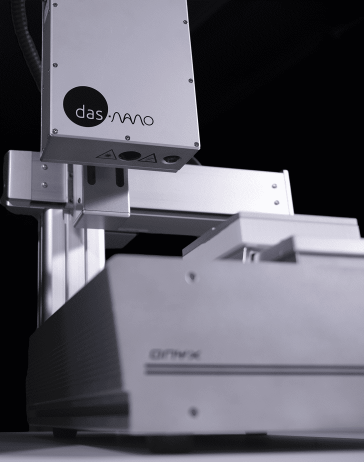

Tailored to any process

Our advanced, terahertz-based technology offers non-destructive inspection with unmatched versatility, adapting seamlessly to meet the unique needs of your production process. Whether integrated into the manufacturing line, in a laboratory, or for field inspections, our solutions ensure accurate and efficient results every time.

Notus

Analytics

- Solutions

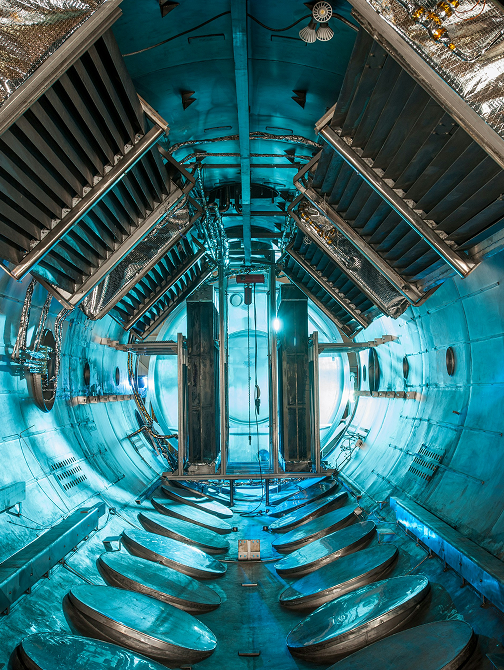

Advanced solutions for quality control with terahertz technology

Optimize processes, reduce costs, and enhance quality with our non-contact inspection technology. Discover our range of advanced, terahertz-based measurement technologies that are transforming quality control.

Discover our range of advanced, terahertz-based measurement technologies that are transforming quality control.

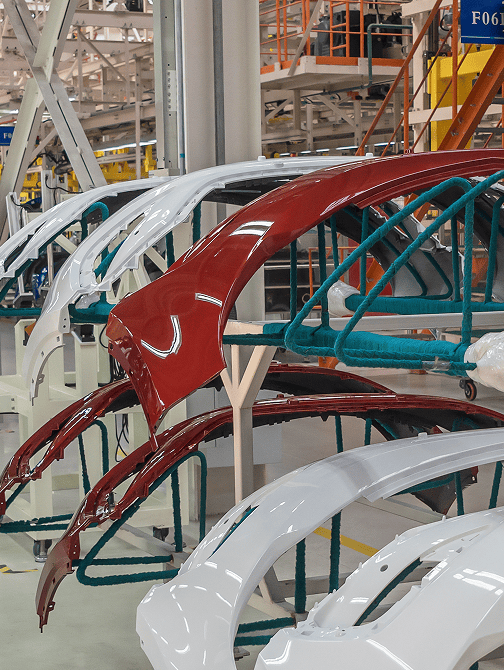

Thickness Measurement

Ensure optimal coating thickness with non-contact, high-precision measurement. Our terahertz technology allows real-time control, reducing material waste and ensuring a flawless finish.

Electrical Characterization

Gain deep insights into the electrical properties of materials with our advanced terahertz-based analysis. Detect conductivity variations and optimize material performance with unmatched precision.

Defect Detection

Reveal what’s hidden beneath the surface. Our terahertz waves penetrate coatings and composite materials to detect corrosion and other defects that traditional methods can’t see.

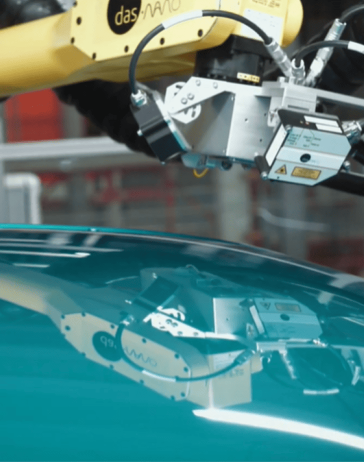

Volkswagen and das-Nano: The world’s first Terahertz car body paint inspection system

“With previous methods, we needed manual processes to measure layer thickness. Now, with das-Nano’s terahertz technology, we have significant time and material savings.”

Claudio Sole

- Highlights from our recent news

At the forefront of industrial transformation

Certified commitment to quality

- Library

Access our knowledge hub

- BUYER’S GUIDE

- Whitepaper

- Whitepaper

- About us