- Wind Power

Precision in blade coating inspection

Rethinking reliability in wind energy

Wind turbine blades endure extreme weather conditions, making their coatings a critical defense against erosion and structural damage. However, traditional inspection methods fall short—visual checks lack reliability, and conventional measurement techniques only assess single layers. The result? Costly repairs, rework, and downtime.

Revolutionizing wind turbine maintenance with terahertz technology

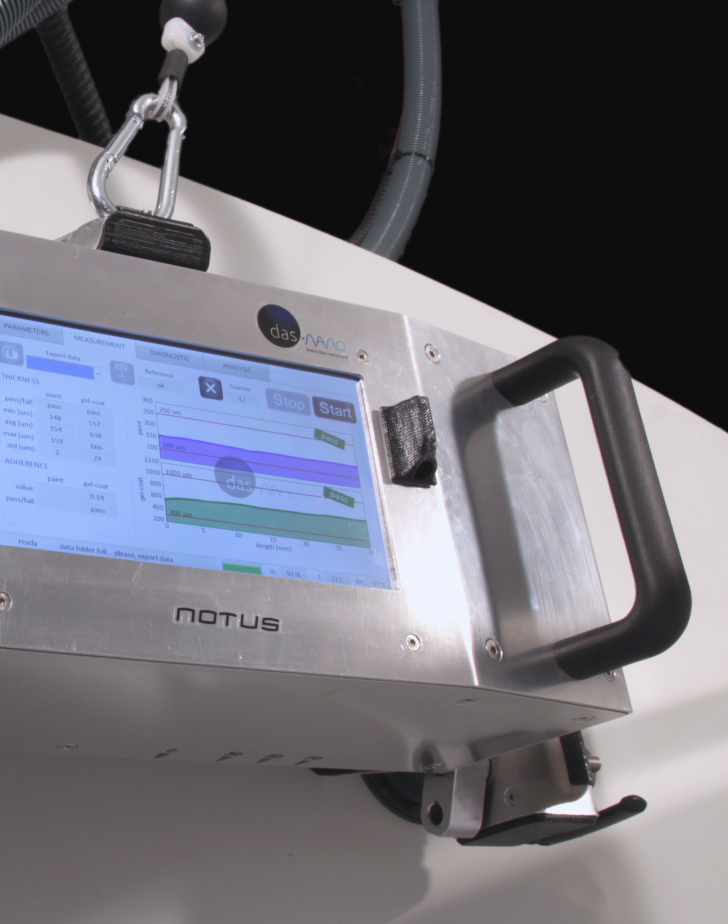

das-Nano brings a new standard to wind blade inspection. Our terahertz-based, non-destructive technology provides precise multilayer coating thickness measurement and adhesion assessment, ensuring early defect detection and real-time quality control.

Tackle industry challenges with cutting-edge solutions

- Reduce maintenance costs

Over 30% of blade maintenance expenses stem from surface defects. Our technology minimizes rework and prevents recurring repairs. - Improve coating reliability

Detect inconsistencies in thickness and adhesion to ensure longer-lasting protection. - Enhance sustainability

Optimize material use and lower environmental impact by reducing coating waste and unnecessary repairs.

- Versatile. Precise. Reliable.

One system, endless possibilities

- Contactless & non-destructive

Inspect coatings without damaging the blade surface. - Fast & Accurate

Get real-time data for immediate corrective action. - Multilayer coating analysis

Measure thickness and adhesion of each individual layer. - Adaptable to any workflow

Available for laboratories, factory production lines, and field inspections. - Seamless automation

Fully compatible with industrial and collaborative robots for effortless integration.

- Success Stories

Trusted by industry leaders

Siemens Gamesa and other global wind energy leaders rely on our technology to prevent internal damage and optimize turbine performance.

- Contact us

Ready to elevate your wind turbine maintenance?

Contact us today to learn how das-Nano can transform your quality control processes.