In aerospace manufacturing, coatings are not just a final aesthetic touch—they are fundamental to performance, safety, and sustainability. A properly applied layer of paint or protective material ensures that aircraft components can withstand extreme atmospheric conditions, maintain aerodynamic efficiency, and perform their critical roles in navigation and structural integrity.

But there’s more to the story: applying just the right amount of coating is also a major lever for improving fuel efficiency. When you multiply a few grams saved across thousands of aircraft surfaces, the impact becomes enormous. Lighter aircraft mean lower fuel consumption, reduced emissions, and more sustainable operations. In commercial aviation, where every flight counts, every micron matters.

A smarter, non-destructive way to measure coatings

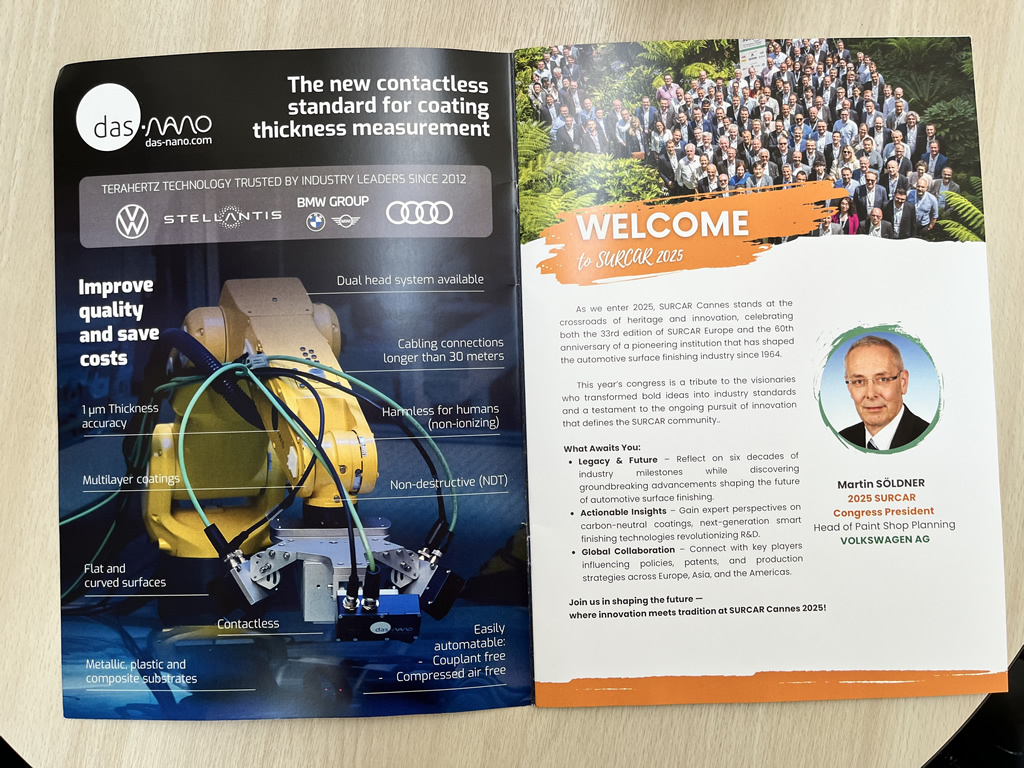

Despite the high stakes, coating thickness measurement has long relied on outdated or destructive inspection methods—slow, invasive processes that often require interrupting production or even damaging parts to verify quality. This is where terahertz technology is proving transformative.

das-Nano’s terahertz systems provide non-contact, real-time measurements of both wet and dry coatings. No need to cut or dismantle a component. No need to wait hours for lab results. These systems are being integrated directly into production lines, delivering instant feedback and helping manufacturers like Airbus improve traceability, reduce rework, and minimize material waste. The result is faster, more precise, and more sustainable aircraft manufacturing.

What to expect at IntAirCoat 2025

At IntAirCoat 2025, Israel Arnedo, Business Unit Director at das-Nano, and Francisco José León Arévalo, Robotics & Automation Expert at Airbus, will present how Airbus is leveraging this breakthrough technology in real-world applications. Their session, Advancing aerospace thickness inspection: precise measurement for wet & dry coatings, will provide a deep dive into how terahertz systems are redefining quality control in aircraft painting—and why it’s becoming a cornerstone of next-generation production lines.

Attendees will discover how precision measurement is helping optimize coating performance while avoiding overuse of materials—contributing to both economic and environmental goals. Moreover, they’ll learn how this collaboration between das-Nano and Airbus is enabling smarter, more agile responses to the demands of modern aerospace manufacturing.

Why this matters more than ever

Aircraft painting is at the intersection of engineering, efficiency, and sustainability. The smallest improvements in this area can cascade into meaningful gains for airlines, manufacturers, and the planet. That’s why innovations like terahertz-based inspection aren’t just technological upgrades—they’re strategic investments in the future of aviation.

As the industry continues to evolve, events like IntAirCoat are essential to connect the dots between cutting-edge research, practical solutions, and the real challenges faced on the factory floor. Don’t miss this opportunity to see what’s next—because in aircraft painting, precision isn’t optional, it’s essential.