- Irys

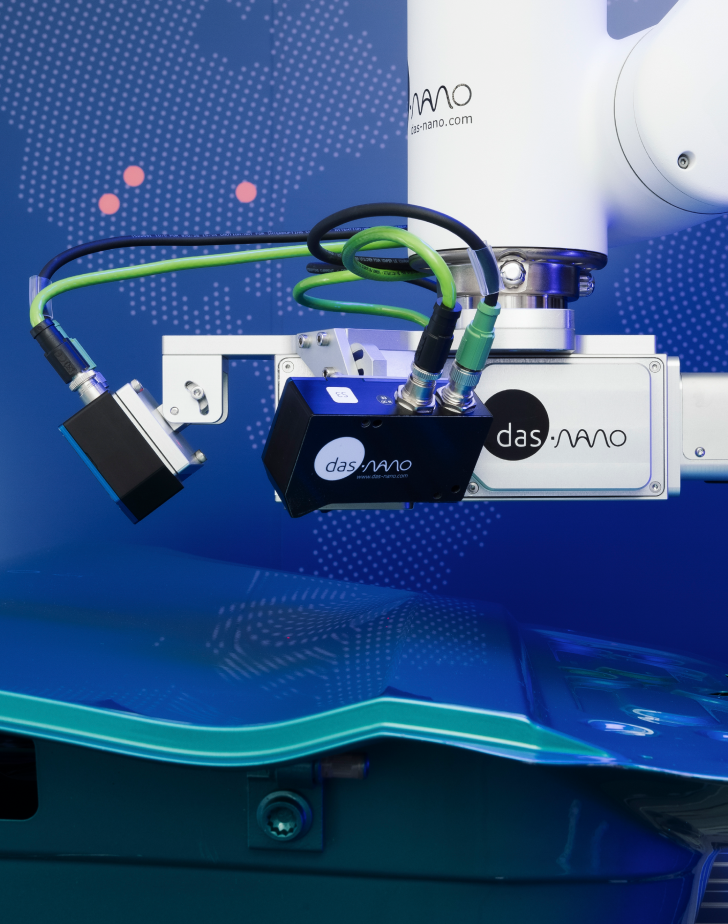

The new contactless standard for coating thickness measurement

Chosen by leading industries worldwide

Irys is revolutionizing non-contact thickness measurement, setting a new standard for precision and efficiency. Industries worldwide are embracing its game-changing technology to optimize quality control like never before.

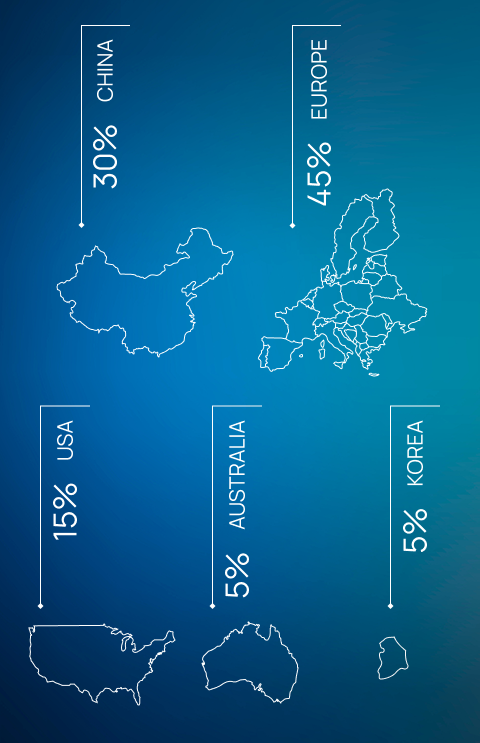

- Global presence

- Global presence

das-Nano technology is trusted by leading manufacturers worldwide. Our customer base spans key regions, reflecting our commitment to innovation and excellence in every market.

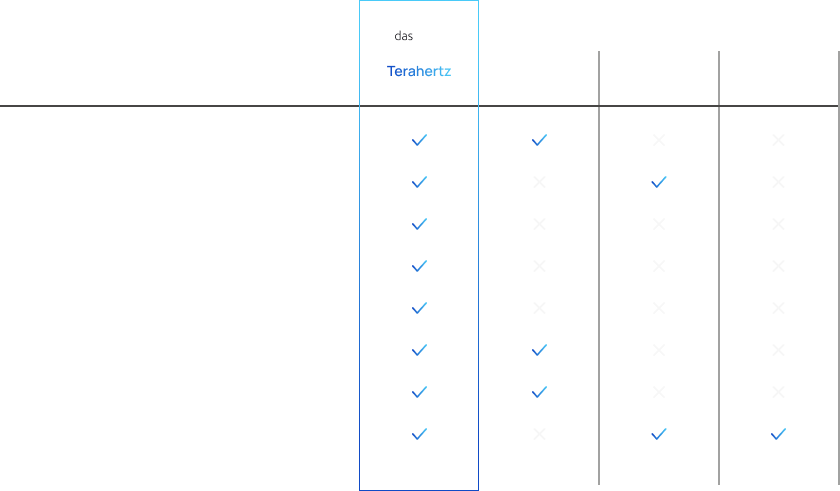

Because not all technologies are created equal

Why are industry leaders choosing Irys?

- Fully contactless

No physical interaction, zero risk of surface damage. - Multi-layer analysis

Measures the thickness of each coating layer in real time. - Substrate-agnostic

Works on metals, composites, and plastics without recalibration.

- Non-destructive

No need for test panels or destructive methods. - Automated and fast

No operator dependency, reducing human error. - Seamless integration

Compatible with existing manufacturing lines, robots and quality control systems.

How it works?

Discover das-Nano Irys in action

das-Nano has met Volkswagen’s challenge with Irys, its patented terahertz-based technology for non-contact, layer-by-layer coating thickness measurement. Selected through an international tender, Irys became the world’s first fully operational paint thickness inspection system at Volkswagen Navarra in July 2020.

Running 24/7 since its installation, it provides unprecedented data on the painting process, enabling a 15% cost reduction through material, energy, and defect minimization—delivering both economic and environmental benefits.

- das-Nano Irys datasheet

A deep dive into the specifications that set our technology apart

In the dynamic landscape of industrial manufacturing, where precision and efficiency are key, the selection of coating thickness measurement technology plays an essential role in ensuring product quality and process optimization.

- Technical excellence in surface Inspection

Precision, Safety, and Versatility in Every Measurement

Contactless measurement for ultimate surface protection

This ensures that delicate surfaces remain undisturbed during the assessment process, which is crucial for preventing damage to intricate coatings.

Non-destructive testing for real-time quality control

Non-destructive testing (NTD) is vital for assessing coating thickness without compromising the integrity of the material, enabling ongoing quality control and notably reducing scrap.

Multilayer analysis with detailed surface mappin

The ability to assess multilayer structures and generate detailed thickness maps enhances the technology versatility and utility in complex coating scenarios.

Unmatched precision with 1 µm accuracy

Precision is crucial, and a high level of accuracy ensures reliable and precise measurements, contributing to quality control standards of ± 1 micrometer.

Automation-ready with no couplants or compressed air

Easy automation enhances efficiency, and eliminating couplants and compressed air simplifies the integration process and reduces operational complexities.

Versatile performance on metal, plastic, and composites

Versatility across different substrates is essential for the technology to cater to diverse manufacturing needs and applications.

Measures flat and curved surfaces with ease

The ability to handle various surface geometries broadens the scope of applications, ensuring suitability for components with intricate shapes without limiting the inspiration of car designers

Safe and non-ionizing technology

Safety is paramount, and it’s crucial to highlight that all terahertz waves are harmless to humans, ensuring the well-being of operators during measurements.

- Optimized for industrial performance

Key features designed to maximize flexibility, efficiency, and reliability

30-meter cabling for flexible deployment

Our technology supports cabling of up to 30 meters, offering exceptional flexibility in deployment. This allows for optimal positioning within the manufacturing environment, ensuring top performance without compromising signal integrity.

Dual-head system for enhanced efficiency

Our dual-head system significantly boosts versatility and efficiency, enabling simultaneous measurements with two robots managed from a single supply unit. This setup is ideal for scenarios where maximizing throughput and precision is essential.

Advanced analytics for smarter decision-making

The existence of a friendly analytics platform enhances the value of the technology by offering tools for data analysis and visualization, contributing to informed decision-making and process optimization.

Fully compatible with industrial robots

Compatibility with standard robots streamlines integration processes, reducing the need for specialized equipment and enhancing overall system flexibility.

IP54. Designed for seamless integration with standard robotic systems

IP54. Designed for seamless integration with standard robotic systemsAn IP54 rating indicates resistance to dust and water, making the technology suitable for deployment in challenging industrial environments with varying conditions.

Dust- and water-resistant, ensuring reliability in demanding industrial conditions

The ability to operate within a broad temperature range enhances applicability, ensuring reliable measurements in automotive manufacturing scenarios.

Dry, wet, and cured paints

Versatility in handling different paint conditions allows the technology to adapt to various stages of the manufacturing process, contributing to real-time quality control.

Automatable & accurate positioning system

Automation coupled with an accurate positioning system contributes to streamlined processes and ensures precise measurements, critical for maintaining quality standards.Expert support to keep operations running

A comprehensive support service ensures that any technical issues or queries can be promptly addressed, minimizing downtime and optimizing system performance.Robust, 24/7 production-proven technology,

The widespread adoption of our technology by top OEMs reflects its exceptional reliability and performance, ensuring its adaptability and effectiveness in a wide range of manufacturing environments.

“With previous methods, we needed manual processes to measure layer thickness. Now, with das-Nano’s terahertz technology, we have significant time and material savings.”

Claudio Sole

“Due to the obsolescence of our previous measurement systems, the Wolfsburg planning department and our technology partner das-Nano, decided to introduced an installation based on Terahertz technology. This system allows us the simultaneous measurement of all paint layers in a fully automated way eliminating manual processes”.

Frank Uhlemann

Adaptable to your needs: das-Nano Irys tailored for every industrial challenge

Discover how das-Nano Irys can be tailored to your manufacturing needs

das-Nano Irys Industrial