At this event, our Director at das-Nano, Israel Arnedo, and Jessie Richardson, Senior Engineer at Toyota North America, led a presentation titled Toyota & das-Nano: paving the way of terahertz film build measurement systems for saving time, materials, and energy. This session was part of the carbon footprint reduction block, one of the main areas of focus at the event.

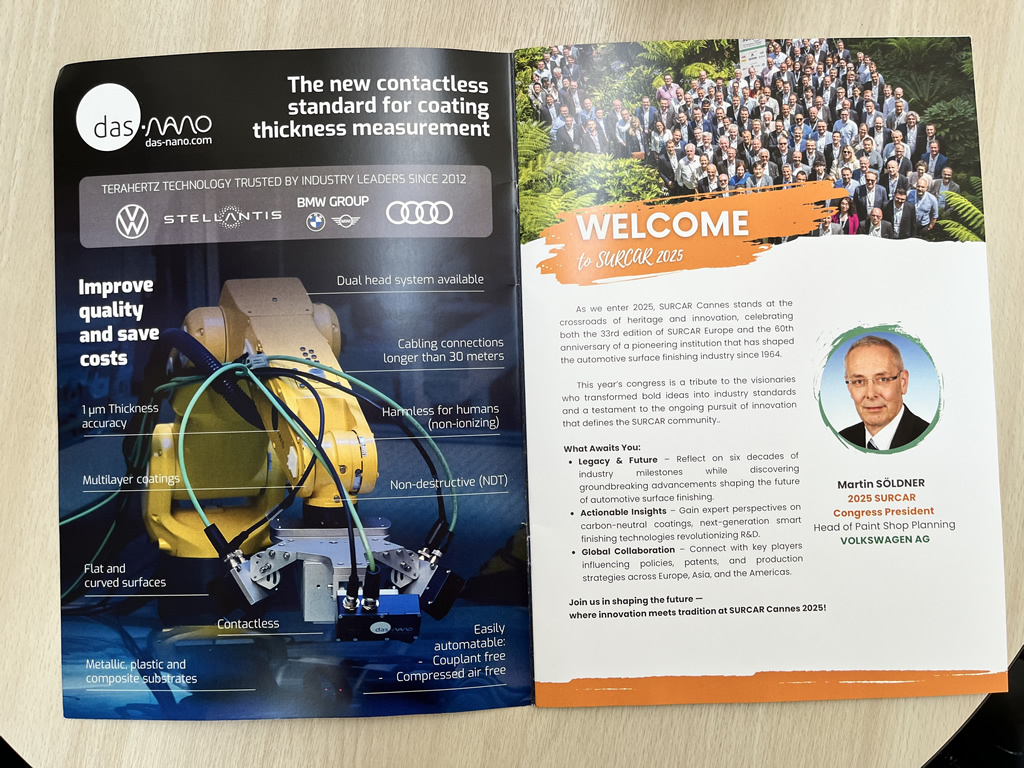

The CARES forum is a reference point in the automotive sector, driven by giants like BMW, Ford, General Motors, Honda, Hyundai, Magna, Nissan, Renault, Stellantis, and Toyota, who unite to collaborate on sustainable production strategies. With an audience of over 300 industry leaders and experts, this event offered a unique opportunity to present our terahertz-based coating thickness measurement system, Irys.

Toyota’s endorsement of Irys technology

Toyota’s support of Irys reflects their extensive testing, where they assessed our system against other equivalent technologies. Toyota concluded that das-Nano’s Irys surpasses competitors in performance, robustness, and precision, making it their preferred choice. This endorsement is a testament to the excellence of our technology, reinforcing Irys as an ideal solution for advancing their production quality and efficiency goals.

The importance of the Irys system in reducing environmental impact

Our Irys technology stood out in the presentation for its capability to perform non-destructive, contactless inspections across multiple paint coating layers—an innovation that significantly outperforms current methods. Developed by das-Nano, this technology not only provides precision comparable to destructive microscope testing but also offers tremendous advantages in speed, labor reduction, and waste minimization. Toyota highlighted several key areas where the Irys system outshines traditional methods:

Superior accuracy and consistency

- Measurements taken with the Irys system showed greater accuracy and consistency compared to current equipment, achieving results on par with destructive microscopic analysis but in a non-destructive manner.

Reduced production cycle time

- Using the Irys system, painted body inspection speeds increase, allowing for improved production cycles without compromising quality.

Ability to inspect challenging areas

- Irys proved effective in inspecting complex zones like edges and areas with high curvature, where traditional methods often fall short.

Measurable environmental impact

- Aligned with Toyota’s 2050 carbon neutrality goals, our system helps reduce CO₂ emissions by tons, along with significant savings in energy and water. These environmental benefits underscore how technology can drive the shift toward greener production.

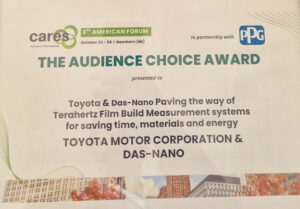

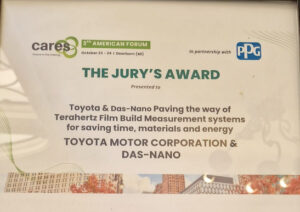

Award-winning innovation

We are proud that this presentation earned two prestigious recognitions at the CARES 2024 forum: the Jury’s Award and the Audience Award. This double accolade reflects the value our technology brings to the industry and the synergy we have achieved with Toyota in developing sustainable and efficient solutions.

These awards highlight not only Irys’s innovative capacity to revolutionize automotive inspection but also the shared commitment between das-Nano and Toyota to reduce environmental impact and optimize efficiency in vehicle manufacturing.

Looking to the future

Our collaboration with Toyota marks a major step forward in the implementation of sustainable measurement technologies and reaffirms our commitment to continuous innovation in enhancing manufacturing processes across the industry. We are working to make technologies like Irys a standard, contributing to more efficient and environmentally-friendly automotive production.

Thank you to all CARES attendees and the Toyota team for their support in this exciting journey toward a greener future.