Carbon fiber substrates are becoming increasingly common due to their lightness and strength, making them ideal for aerospace, wind energy, and automotive industries.

However, professionals involved in painting carbon fiber substrates are well aware of the challenges in controlling the thickness on this material. Unlike metal or plastic, carbon fiber is not perfectly smooth, and its fiber structure has historically made the measurement impossible.

Up to 7 coating layers on carbon fiber

das-Nano, with its Irys system based on terahertz wave technology, can now precisely measure each coating layer on carbon fiber with an accuracy of one micron. For a client, das-Nano, with its Irys technology, has successfully measured up to 7 coating layers on carbon fiber. This achievement represents a significant advancement for industry leaders, providing them with top-notch technology to control coating layers accurately without contact and non-destructively, ensuring the highest quality finishes.

Whether the measurements are conducted on flat or curved surfaces, das-Nano can accurately measure the thickness of the coating layers on carbon fiber, matching the results previously obtained through destructive methods involving material cuts analyzed under a microscope.

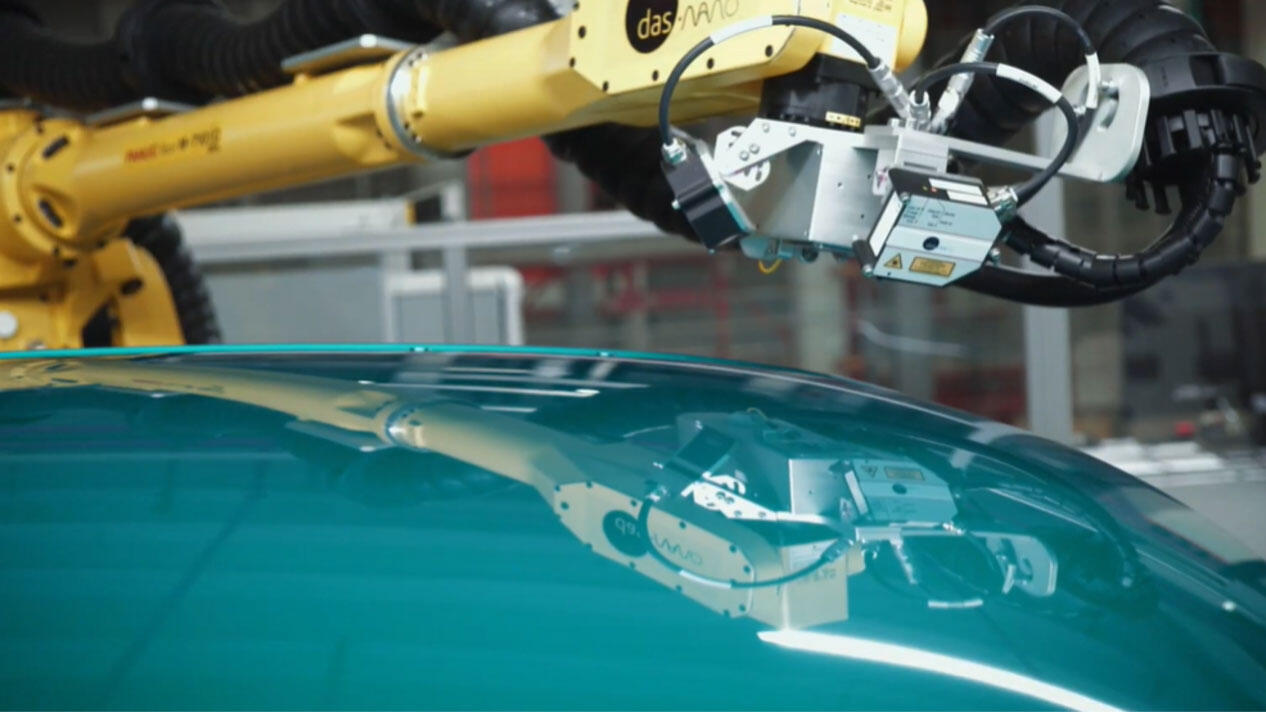

With Irys from das-Nano, the industry no longer needs to touch or break any piece to analyze coating layer thickness. Moreover, this can be done wholly automated on the manufacturing line, as das-Nano’s technology can be mounted on any robotic arm (regardless of brand), providing a complete 360º map with numerous measurement points within seconds.

das-Nano, more than 11 years of research and development serving the industry

das-Nano, with over 11 years of research and development, is the world’s leader in terahertz wave technology for coating layer thickness measurement, with 85% of global installations in this field. Manufacturers in the automotive, aviation, maritime, and wind energy sectors trust das-Nano’s patented technology for its outstanding performance, allowing them to enhance manufacturing processes and quality control in unprecedented ways.

Thanks to terahertz wave technology, measuring the thicknesses of the coating layers on surfaces without contact and non-destructively is now possible. This can be done with micrometer precision, adapting to fully automated industrial environments as well as collaborative settings like laboratories.

Measuring the thickness of coating layers

Measuring coating layer thickness on various surfaces, whether plastic, metal, or carbon fiber, is crucial for:

- Corrosion Prevention and Substrate Protection: Protecting the base material (or substrate) from external agents that could affect its durability or performance.

- Aesthetic Perception: Ensuring a perfect finish for users and buyers.

- Efficiency: Improving the efficiency of raw material use and quality control in finishing.

- Product Performance: Optimizing product performance, considering factors such as the optimal weight of the coating and aerodynamics.

Irys by das-Nano: Innovation and Technology that make a difference

Irys by das-Nano represents more than 11 years of research and development, leading the segment since 2012. The company provides customers with significant benefits, including:

- Cost Savings in Raw Materials: Efficient application of coating layers translates into cost savings in raw materials, contributing to manufacturing process profitability.

- Reduced Environmental Impact: By making processes more efficient, das-Nano’s technology helps reduce the environmental impact of manufacturing, promoting sustainable practices.

- Improved Quality Control: By avoiding waste, defective products, and rework, Irys becomes a crucial ally by providing precise and reliable quality control. It offers real-time information, enabling faster reactions and analysis of vast data, enhancing decision-making and ensuring traceability for each manufactured piece.