This past July, I had the privilege of attending the ‘Strategies in Car Body Painting 2024’ event in Berlin, Germany, organized by the esteemed Automotive Circle. Over two intense days, industry leaders gathered to discuss the future of automotive manufacturing, particularly focusing on innovative strategies for car body painting.

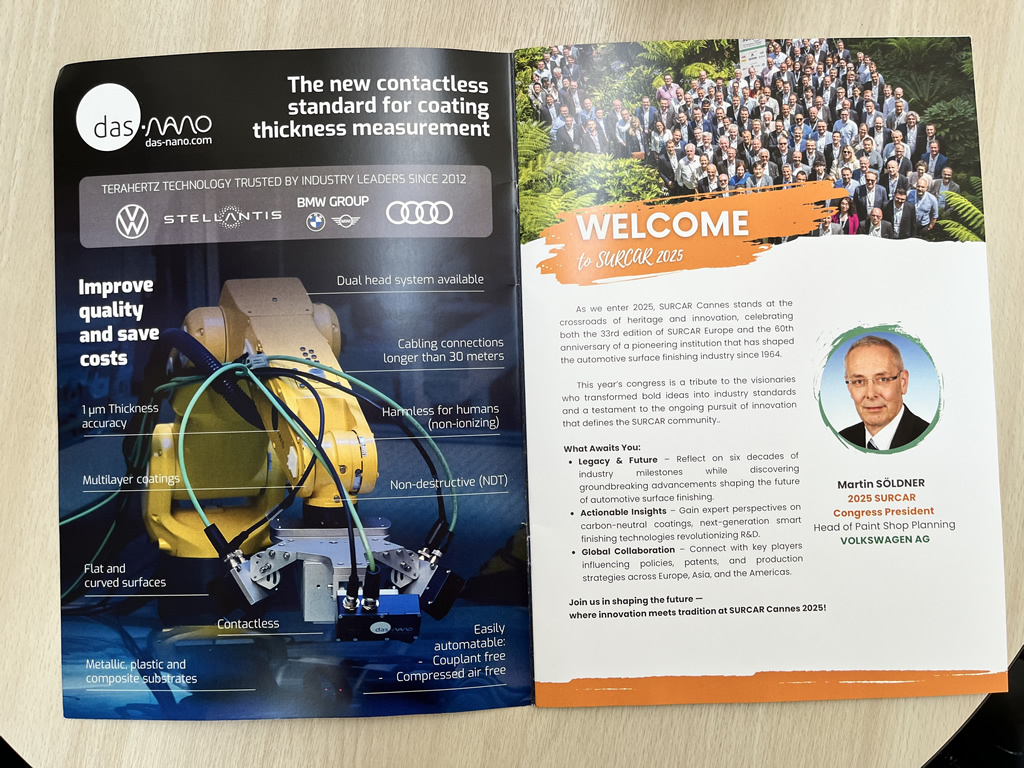

One of the event’s highlights was the lecture I co-delivered with Claudio Sole from Volkswagen, titled ‘Terahertz Measuring System in the Automotive Industry.’ This session provided a unique opportunity to explore how terahertz technology is revolutionizing the way car manufacturers measure and control coating and paint layers.

The Shift in Coating Measurement Technologies

The methods car manufacturers use to measure and control the thickness of coatings and paint layers on vehicles are evolving rapidly. Traditional techniques like inductive, photothermal, and ultrasonic technologies have served the industry well, but they come with limitations. These methods often struggle to measure different coating layers simultaneously, require varying degrees of contact, or fail to work across diverse substrates.

During his speech, Claudio highlighted Volkswagen’s pioneering efforts in adopting terahertz wave-based technologies for coating thickness measurement. He emphasized that:

“Volkswagen has been a pioneer in incorporating terahertz wave-based technologies for coating thickness measurement. We are leaving behind inductive, photothermal, or ultrasonic technologies that are limited in measuring different coating layers simultaneously, require varying degrees of contact, or cannot work on all types of substrates. With das-Nano’s terahertz wave technology, with whom we already have 6 installations around the world, we can overcome these challenges, significantly improving efficiency, saving time and raw materials, avoiding rework, enhancing quality control, and reducing our environmental impact.“

The Advantages of Terahertz Wave Technology

At das-Nano, we’ve developed a terahertz wave technology that offers several advantages over traditional methods. As I explained during the event, our technology provides high spatial resolution far below the millimeter, down to the micron level. It can penetrate the different layers of a coating applied on different substrates as metals, plastics or carbon fibers, enabling us to deliver a fully automated system that doesn’t require extensive calibration time.

This technology, which Volkswagen Navarra has been pioneering since 2020, is emerging as the new standard for measuring thickness and quality control in the paint process. The impact is clear: To date, manufacturers of 6 major OEMs in 13 plants can now automate processes, measure coatings quickly and without contact, and generate complete measurement maps that provide real-time information to the paint team.

Eye-Opening Figures and Industry Impact

The figures we shared during the lecture were eye-opening for many attendees. With technology like das-Nano’s terahertz wave system, the potential for automation, efficiency, and sustainability in automotive manufacturing is immense. This breakthrough allows manufacturers to avoid costly rework, enhance quality control, and significantly reduce their environmental impact by saving raw materials, energy and time.

Collaborating with Industry Leaders

It was an honor for das-Nano to be an official sponsor of the event, alongside Geico SpA and TESA. Sharing the stage and exchanging knowledge with key industry players such as Stellantis, AUDI, Mercedes-Benz, Porsche, Renault, Nissan, BMW, Toyota, Volvo, Ford, and Jaguar Land Rover was an enriching experience.

We also had the pleasure of collaborating with leading technology and research institutions like Dürr, AOM-Systems, Fraunhofer-Gesellschaft, Axalta, Evonik, BASF, and PPG.

Conclusion

In conclusion, the ‘Strategies in Car Body Painting 2024’ event was a significant milestone for das-Nano and the automotive industry. The shift towards terahertz wave technology is setting new standards in quality control, efficiency, and sustainability. As we move forward, we are excited to continue innovating and leading the way in coating thickness measurement.

A big thank you to the Automotive Circle International OEM Advisory Board and everyone who contributed to making this event a success. We look forward to future collaborations and advancements in the field.