- Thickness Measurement

Optimize coating thickness with real-time, contactless measurement

Why precise coating thickness measurement matters

Achieving perfect coating thickness is critical for quality, cost efficiency, and sustainability—but traditional measurement methods fall short.

- Improve durability, aesthetics, and efficiency with optimized coating layers.

- Reduce costs and reworks with real-time, non-destructive measurement.

- Move beyond slow, outdated methods like destructive testing, X-rays, and ultrasounds.

Terahertz (THz) time-domain spectroscopy

Unlocking advanced material insights with cutting-edge terahertz technology.

Why THz?

- Contactless & non-destructive

No sample preparation, no surface damage. - High spatial resolution

Detect details at a sub-millimeter scale. - Deep penetration

Measures coatings and materials up to several millimeters deep. - Time-domain analysis

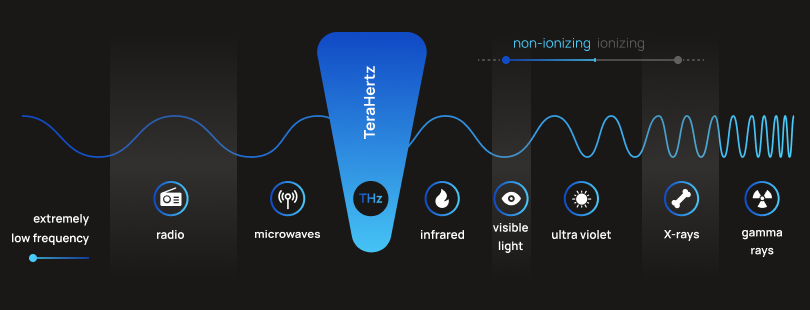

Provides depth-resolved layer information. - Safe & non-ionizing –

100% harmless to humans.

What can you measure?

- Multilayer coatings

Precise thickness measurement of each layer. - Dielectric materials

Accurate refractive index analysis. - 2D materials & thin films

Electrical properties such as conductance, reflectance, and carrier mobility.

The THz smart solution: non-destructive, substrate-agnostic, and fully automated

- Advanced Terahertz technology ensures precise, real-time thickness measurement on any substrate.

- Automate quality control to reduce material waste, energy consumption, and production delays.

- Gain full process control with instant data insights for optimized performance.

Industries that benefit from advanced coating measurement

This technology is essential for industries where coating thickness impacts performance, durability, and cost efficiency:

Automotive

Ensure perfect paint application while reducing material waste and defects.

Aerospace

Meet strict safety and quality standards with precise coating control.

Battery manufacturing

Optimize electrode coatings for enhanced energy efficiency and longevity.

Industrial coatings

Improve corrosion resistance and durability in high-performance applications.

- Proven results: cost savings, efficiency, and sustainability

5%

Less material waste

Reduce excess coating while maintaining quality.

15%

Total cost reduction

Save on materials, energy, and defect-related losses.

3%

Fewer reworks

Improve quality and reduce production errors.

ROI in <1.5 years

Achieve full payback in less than 18 months, significantly accelerating your return on investment and cost efficiency.

Unmatched execution speed

A fully automated system that delivers real-time measurements without the need for extensive calibrations, ensuring seamless integration into your production line.

Experience the power of real-time, contactless coating thickness measurement. Discover how das-Nano Irys transforms quality control with unmatched precision, automation, and efficiency.

- Contact

Upgrade your coating quality control today

Discover how leading manufacturers are optimizing their paint shops.