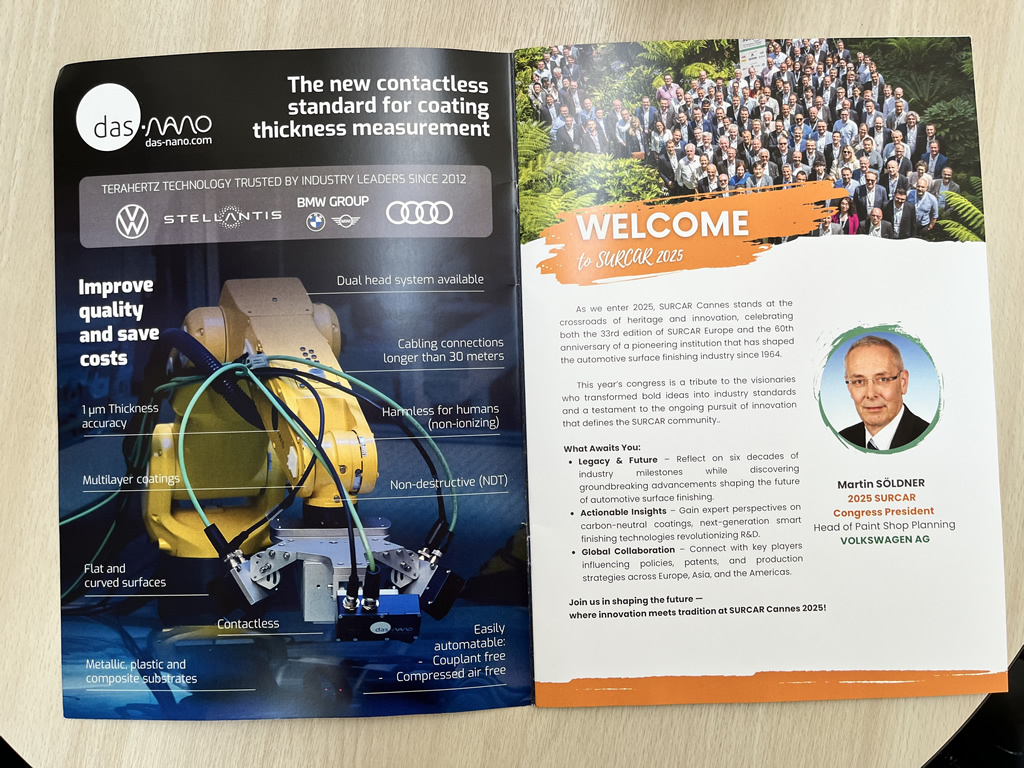

At the latest edition of SURCAR America in Detroit, das-Nano joined Volkswagen of America on stage to present a powerful case study: how the Chattanooga plant is using terahertz technology to bring automotive paint control into a new era of accuracy, sustainability, and process integration.

The joint session, led by David de Ita Cabrera (Paint Process and Planning Manager at Volkswagen of America) and John Oliver (Business Development Manager USA at das-Nano), detailed how the Irys system is enabling measurable improvements in production efficiency, quality assurance, and cost optimization.

From manual checks to real-time data: transforming quality control in automotive paint shops

Before implementing Irys, the Chattanooga plant relied on online basecoat-only checks and limited offline film thickness measurements performed manually by third-party contractors. With the integration of das-Nano’s terahertz-based technology, Volkswagen Chattanooga now performs 100% offline inspections on up to 129 car bodies per day, capturing 80 high-precision measurement points in a 3.8-minute cycle.

“What impressed us the most was the speed and consistency of das-Nano’s system. Achieving 80 accurate measurement points in less than 4 minutes, with both robot heads consistently within 1 μm of each other, gives us a level of confidence we didn’t have before. This allows us to take action immediately, improve our paint process, and ultimately reduce material consumption and defects.”

DAVID DE ITA | Paint Process and Planning Manager at Volkswagen of America

Data precision that drives performance

Over just three weeks of production data, the results spoke for themselves. The Irys system identified disparities in basecoat thickness between paint lines, areas with excessive film build, and opportunities to adjust the e-coat while remaining within nominal definitions. In all cases, the system provided actionable insights backed by real-time data and statistical rigor.

With thickness accuracy below 1 μm and robust analytics through das-Nano’s visualization platform, engineers now have a detailed understanding of layer behavior across every car model and color in production—enabling smarter decisions, faster optimizations, and fewer reworks.

Easy integration, maximum value

das-Nano’s Irys system was chosen not just for its technological accuracy but for its seamless integration into the existing production environment. “We needed a system that would enhance our capabilities without disrupting our workflows,” said David de Ita. “das-Nano delivered exactly that.”

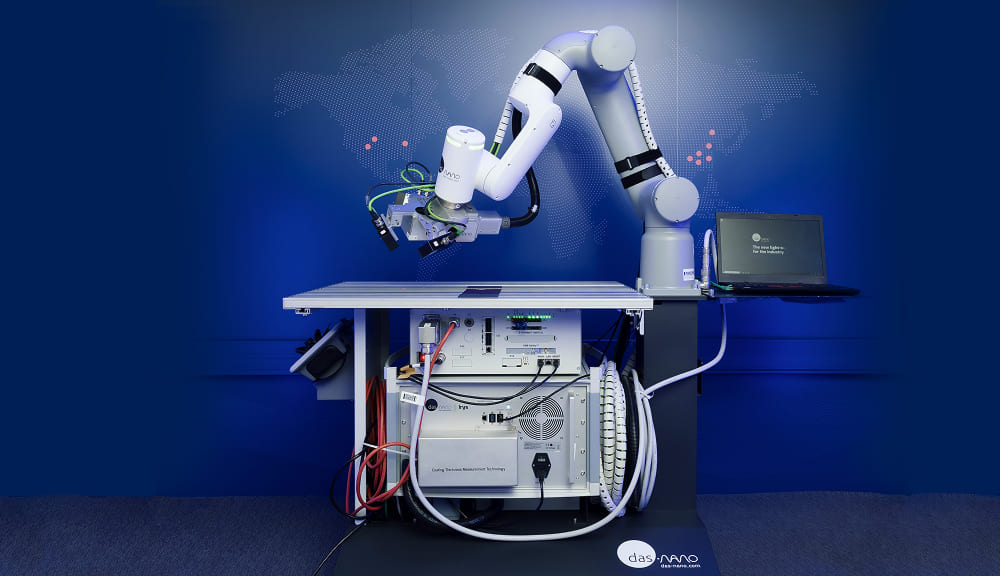

Designed for compatibility with both legacy systems and new defectology, color, or structure control cells, Irys provides flexible deployment options—from fully automated dual-head robots to cobot-based solutions for simpler installations. Whether retrofitting an existing plant or designing a new quality cell from scratch, Irys fits.