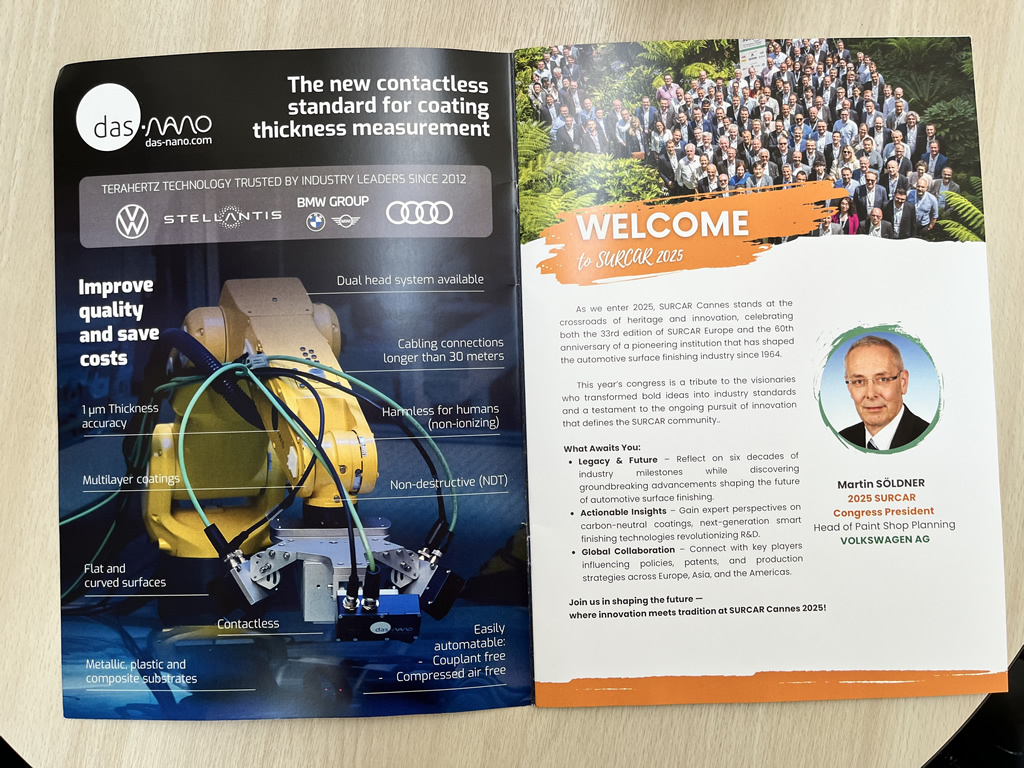

Volkswagen Group and das-Nano: redefining coating thickness control at SURCAR Europe 2025 Following our successful joint presentation at SURCAR America, das-Nano and Volkswagen tookthe stage again—this time at SURCAR Europe 2025 in Cannes. In a technically-focused session, Claudio Sole (Volkswagen AG) and John Oliver (das-Nano) presented how terahertz-based measurement is changing the way automotive manufacturers approach multilayer coatingcontrol—driving both process excellence and sustainability.

Real world validation from one of the industry’s leaders

“das-Nano’s terahertz system gives us the accuracy, repeatability, and reliability we need to

monitor multilayer coating processes in real time — without cutting panels or interrupting production. We are no longer talking about lab demos — this is production – ready tech deployed across several of our plants” Claudio Sole, Head of Paint Shop Quality at Volkswagen AG

This statement reflects how das-Nano’s Irys system is no longer a future promise but a mature, proven solution—already running in production lines around the world, with installations across Europe, Asia, and the United States.

From microscopy to terahertz: redefining the standard

The session featured direct comparisons between terahertz measurements and traditional microscopy across multiple OEM use cases. The results spoke for themselves: Irys consistently matched microscopic readings within ±1 μm across all layers (clear coat, basecoat,primer, ande-coat).

Repeatability and reproducibility studies—commonly referred to as R&R studies—confirmed thereliability of the system. Standard deviations were consistently below 0.5 μm across 50 measurement cycles, even when measuring multiple pointsand layers.

A scalable, flexible technology for modern plants

Beyond accuracy, Irys was praised for its ease of integration. Volkswagen and other OEMs are successfully deploying it across both new and existing production environments, thanks to its non-contact, non-destructive architecture, dual-head robotic options, and compatibility with both metallic and non-metallic substrates.

The system also connects seamlessly to das-Nano Analytics, a big data platform that enables engineering teams to analyze thousands of measurements across models, substrates, and production shifts in real time.

Sustainability through control

A key takeaway from Cannes: precision is sustainability. Irys reduces overspray and unnecessary material use while minimizing reworks—leading to measurable savings in cost, energy, and environmental footprint. This makes terahertz measurement not only a tool for quality assurance, but also for sustainability and process efficiency.

das-Nano: setting the benchmark in coating measurement

With global deployments, top-tier OEM validations, and a system that bridges precision, speed, and automation, das-Nano is helping redefine the industry’s standard for coating thickness measurement. As highlighted in Cannes, terahertz isn’t an experimental technology anymore—it’s the new reality in advanced automotive manufacturing.