Terahertz (THz) waves can pass through most dielectric materials with a penetration of the order of cm. They can “see” beneath the surface layers of materials such as plastics, pharmaceuticals, paper, cardboard, textiles, paints, etc.

To extract information from a material, a beam of terahertz waves is impinged on the surface of the material. The beam travels through the material, interacting with each layer interface. The reflected or transmitted beam is collected by a terahertz detector, from which information about the electrical properties and thickness of each layer is extracted.

This technique is contactless and non-destructive. Measurements are fast (less than 1 second) and accurate (up to 1 micron thickness) and allow obtaining information of every layer in multilayer systems in a simultaneous way.

Examples of corroded car and boat

It is the wear or alteration of metal, either by direct chemical attack or by electrochemical reaction.

Metallic substrates predominate in the vast majority of car bodies, aircraft, ships, etc. So rust or corrosion is an aspect that should not be neglected. It is a chemical reaction that occurs due to the contact between metals and oxygen, a phenomenon that must be continuously controlled from the moment it starts to prevent it from gaining ground and becoming a much greater complication.

Corrosion can go unnoticed before our eyes, under layers of paint, plastic films, etc, with no obvious signs of its appearance at first sight.

The deterioration caused by corrosion is enormous. If it is still possible to act in time, it can be very costly, besides being a safety risk. To avoid the deterioration of buildings, automobiles, industrial machinery, ships, bridges, etc., the most important thing is prevention and identification at the earliest stage possible. Determining the causes of metal corrosion is essential.

We have found the solution with our terahertz waves technology. This technique is non-contact and non-destructive. Measurements are fast (less than 1 second) and allow obtaining information about thickness and electrical parameters of each layer in multilayer systems simultaneously, being able to differentiate metallic surfaces from oxidized ones.

Optimize your process making it more efficient

They can pass through most dielectric materials, with a penetration of the order of cm. In this context, they can “see” below the surface layers of materials such as paints, varnishes, plastics, pharmaceuticals, paper, cardboard, ceramics, wood, composites, textiles, etc. They are low-energy, non-ionizing waves and are therefore harmless to humans. These characteristics of THz waves introduce a new way of seeing what was not visible before.

In the current era of technology and industry, companies in the automotive, wind energy, aeronautics, and marine sectors, among others, are constantly looking to incorporate new technologies and intelligent systems into their production lines to improve the quality of their products and increase their production efficiency by reducing costs and production times.

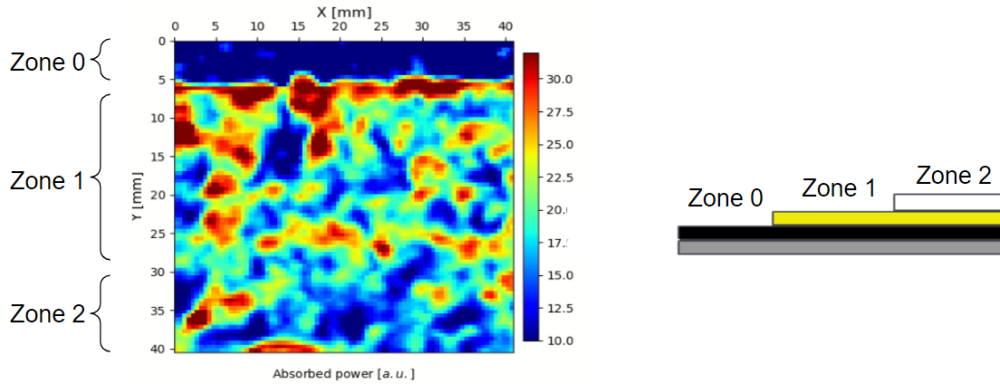

We have studied multiple corroded and non-corroded metallic substrates coated with different materials. Multiple points of each sample can be measured very quickly to map the whole sample. The terahertz beam impinged onto the surface is more strongly absorbed by oxidized areas than by metallic areas. In this sense, an absorbed power map of the sample shows the corroded and non-corroded areas.

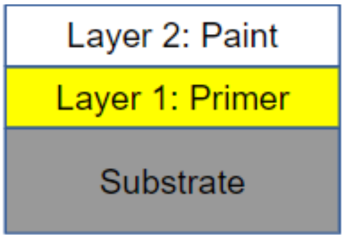

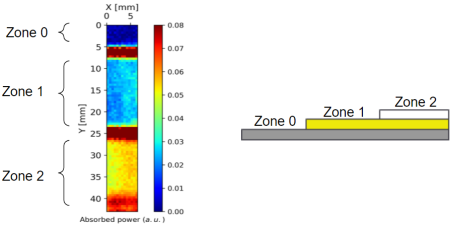

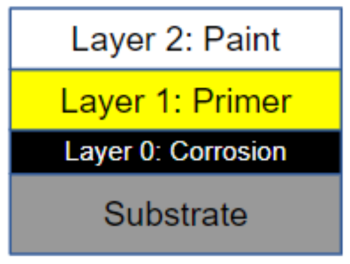

As an example, you can see the terahertz study of a non-corroded and a corroded sample with two layers (primer and paint) onto a metallic substrate.

The non-corroded sample (on the right), presents null absorbed power in the metallic surface or substrate (zone 0) and very low absorbed power in the coated areas (zone 1 and 2; absorbed power values lower than 0.07). The higher absorption in zone 2 is coherent with the higher amount of material deposited onto the metallic surface. The low absorbed power values and the homogeneity in each painted zone indicates the absence of corrosion in the substrate. Note that the interfaces between the layers or zones present a higher power absorbed due to the edge effect, a physical effect related to the terahertz waves interaction with matter (it is not related to corrosion).

On the other hand, the corroded sample presents absorption power values around 10 in the metallic surface (zone 0) and absorption power values between 10 and 30 in the coated areas (zones 1 and 2). Both the higher absorption power values and the heterogeneity of the results map in zones 1 and 2 indicates the presence of corrosion under the coating layers.

In conclusion, thanks to our terahertz technology, corroded metallic substrates under coatings can be easily identified by analyzing the absorbed power of the Terahertz impinged beam.

das-Nano Group