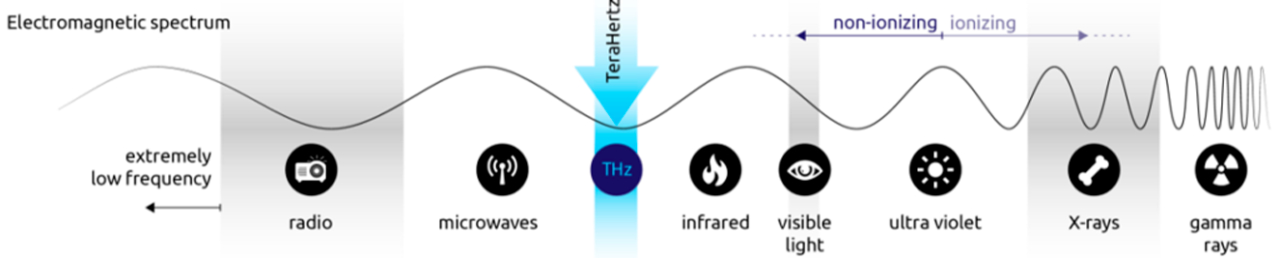

Terahertz waves, also known as T-waves, are electromagnetic waves located between microwaves and infrared rays in the electromagnetic spectrum. Terahertz radiation is typically understood as electromagnetic radiation in the frequency range from approximately 0.1 THz to 10 THz, corresponding to wavelengths from 3 mm to 30 μm in vacuum. Such frequencies are higher than those of radio waves and microwaves, but lower than those of infrared light. Since the wavelengths are in the range of 0.03 mm to 3 mm, and often below 1 mm, terahertz radiation is also sometimes called submillimeter radiation. In addition, at least the higher frequency part of the terahertz region can also be called far infrared.

This section of the radio spectrum has unique characteristics and properties, they can see beyond materials such as plastics, fabrics, paper and cardboard. There are many materials that have the peculiarity that their characteristics can be studied through absorption lines. Taking advantage of this capability we may be able to detect the “fingerprint” of many biomolecules, proteins, explosives, narcotics…

Terahertz technology has been known since the beginning of the 20th century, but its application was not possible until three decades ago due to the lack of material means for the correct generation and detection of these waves.

For a long time, terahertz radiation was little used in science and technology, essentially because there were no good terahertz sources or suitable detectors available; this spectral range was often called the terahertz gap. This gradually changed until the 1990s, when interest in terahertz waves grew strongly, and more and more researchers became involved in this area.

The rapid advances in the field are largely due to advances in photonics, which created several solutions for both the generation and detection of terahertz waves, as well as for modulating terahertz signals. These advances have strengthened the motivation for new efforts in various areas of terahertz technology, and the rapidly increasing technology options also open up a wide field of applications.

At present, there are only a few companies in the world dedicated to the manufacture of terahertz spectrometers, designed primarily for scientific research. das-Nano goes beyond and comes up with solutions to industrial problems by applying terahertz technology.

The electromagnetic spectrum ranges from shorter wavelength radiation (higher frequency), such as gamma rays and X-rays, through ultraviolet radiation, visible light, and infrared radiation, to longer wavelength electromagnetic waves (lower frequency), such as radio waves.

The study and control of electromagnetic waves of different frequencies or wavelengths, has allowed the development of important technological advances during the last centuries. Some of these advances have taken root so quickly and deeply that we can hardly remember how we functioned before they appeared. A clear example of this is the use of microwave waves for wireless communication, which makes possible the operation of cell phones, WIFI networks, etc.

However, despite the significant progress achieved, there is still a band within the entire electromagnetic spectrum with excellent properties that remains virtually unexplored: the terahertz band. Thus, electromagnetic waves with a frequency of the order of 1012 Hertz are known as T-waves or T-rays. The use of the electromagnetic spectrum in the terahertz range is called terahertz spectroscopy.

Terahertz waves also have a high potential to transform the state of the art of today’s technology, just as X-rays, infrared waves or microwaves have had in the past.

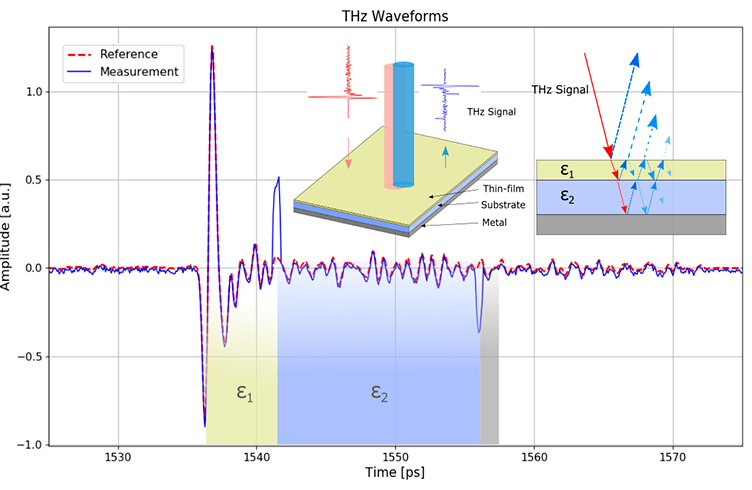

To extract information from a material, a beam of THz waves is impinged on the surface of the material. The beam travels through the material, interacting with each layer interface. The reflected or transmitted beam is collected by a detector, from which information about the electrical properties and thickness of each layer is extracted. A reference measurement can be also taken from a metallic surface to be compared with the sample measurement.

Schemes of the interaction of a terahertz beam with a multilayer material composed of a metal, a dielectric substrate and a thin film. Representation of two terahertz waveforms in the time-domain, along with the identification of the peaks corresponding to the air-thin film, thin film-substrate and substrate-metal interfaces.

Passive systems consist solely and exclusively of THz receivers, the emitter being the element or sample to be observed. They are compact and low cost but lack robustness and reliability.

Active systems require an external THz source to illuminate the element or sample to be inspected and a receiver to detect the THz waves after interaction with the sample. The interacti

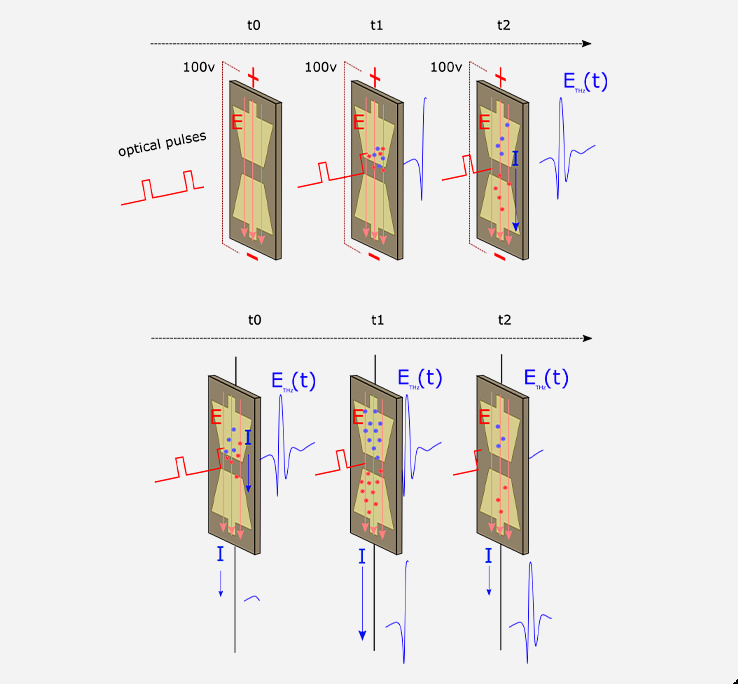

The interaction of the element or sample with the THz waves will modify said waves and such modification will be used to extract information from the sample. Logically these systems will be more robust and reliable than the passive ones at the cost of increasing their cost and size. One of the most mature technologies with which these active systems are implemented is the one that uses photoconductive antennas (PC Antenna) as generator and receiver. In these systems a laser pulse of very short duration (femtoseconds) is impinged on the polarized antenna with a constant voltage, from which the THz pulse is generated. Over the years, alternative designs for the antennas have emerged depending on the performance required in terms of working bandwidth and antenna radiation pattern. To increase the power of the radiated pulse, different solutions have been developed such as the use of large-aperture emitters, known as large-aperture photoconductive emitters.

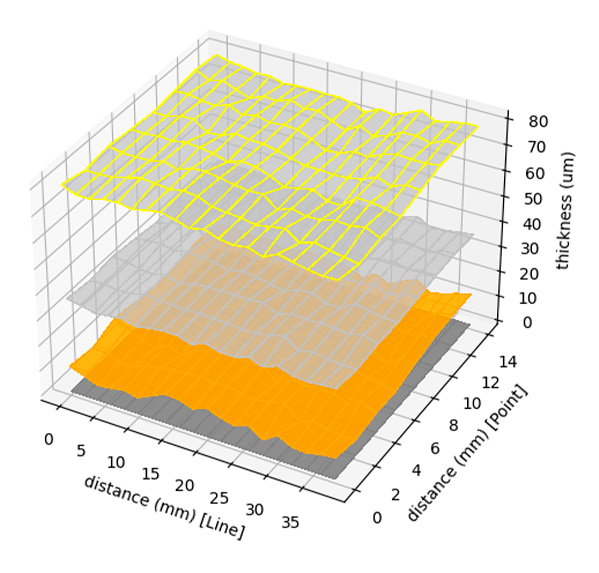

This technique is contactless and non-destructive. Measurements are fast (less than 1 second) and accurate (up to 1 micron) and allow obtaining information of every layer in multilayer systems in a simultaneous way.

IEC TS 62607-6-10:2021 Nanomanufacturing – Key control characteristics – Part 6-10: Graphene-based material – Sheet resistance: Terahertz time-domain spectroscopy.

DIN 50996:2020-05 Non-conductive coatings – Non-destructive measurement of coating thickness – Terahertz measurement method (in German)

VDI/VDE 5590 Blatt 1:2018-03 Terahertz systems – Terms and definitions (in German and English).

VDI/VDE 5590 Blatt 2:2022-01 Terahertz systems – Time domain spectroscopy (TDS) systems (in German and English).

Their distinctive feature is their ability to penetrate through most dielectric materials (such as plastics, ceramics, pharmaceuticals, insulation, textiles, or wood), which opens up a world of possibilities for nondestructive testing (NDT). At the same time, many materials exhibit identifiable frequency fingerprints at THz frequencies that can enable material identification and quantification. These two characteristics of THz combined introduce a new way of seeing what was previously not visible. Because of its low photon energy, it does not cause ionization, is completely safe, and does not modify the inspected item.

In the current era of technology and industry, companies in the automotive, wind energy, aeronautics, and marine sectors are constantly looking for incorporate new technologies and intelligent systems into their production lines that will enable them to improve the quality of their products and increase their production efficiency by reducing costs and production times.

Determine layer thicknesses, number of layers, defects, air bubbles or hidden characteristics in non-metallic materials.

Obtain visual images of everything mentioned in the previous point, which represents very relevant information in many cases.

Obtain the absorption spectrum or spectral fingerprint of a substance, without contact, instantaneously and even crossing barriers upstream of the product.

3D representation of the thickness of three layers in a multilayer sample obtained with terahertz spectroscopy.

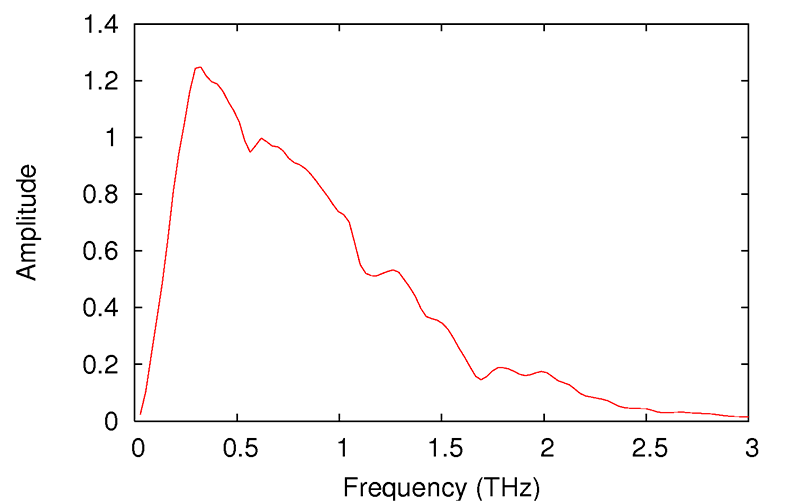

Representative terahertz spectrum (source: Wikipedia)

Applications include materials characterization and identification. It also has benefits in the fields of communications, imaging, medical diagnostics, health monitoring, environmental control, and chemical and biological detection, as well as safety and quality-control applications.

Irys is a contact-less system that using Terahertz waves and proprietary algorithms developed by das-Nano provides the thickness measurement of every painting layer in a car body in a non-destructive way.

Onyx is the first system in the market designed to provide a full-area non-destructive characterization of Graphene, thin-films, and other 2D materials.

Notus enables the inspection of the full layer thickness measurement and adherence control of each coating layer on top of composite materials used in the wind and aerospace industry.

das-Nano Group